Mulberry bushes at Angkor d' Artisans

Five thousand years ago, when modern forms of writing had not yet been invented and Egyptian hieroglyphics were just developing, some farmer or worker or emperor of China discovered silk making. I wonder what induced that person to look in the mulberry bushes, pick through the tiny silk worm cocoons, and spin them into thread.

|

|

|

|

Silk is something we take for granted, now. It is another fabric that we can pick up in markets, stores, and boutiques. We line our purses, wrap our necks, and clothe ourselves in dresses and shirts all made of silk. We had no idea how much labor goes into producing a small silk scarf until we visited Artisans d'Angkor in Siem Reap.

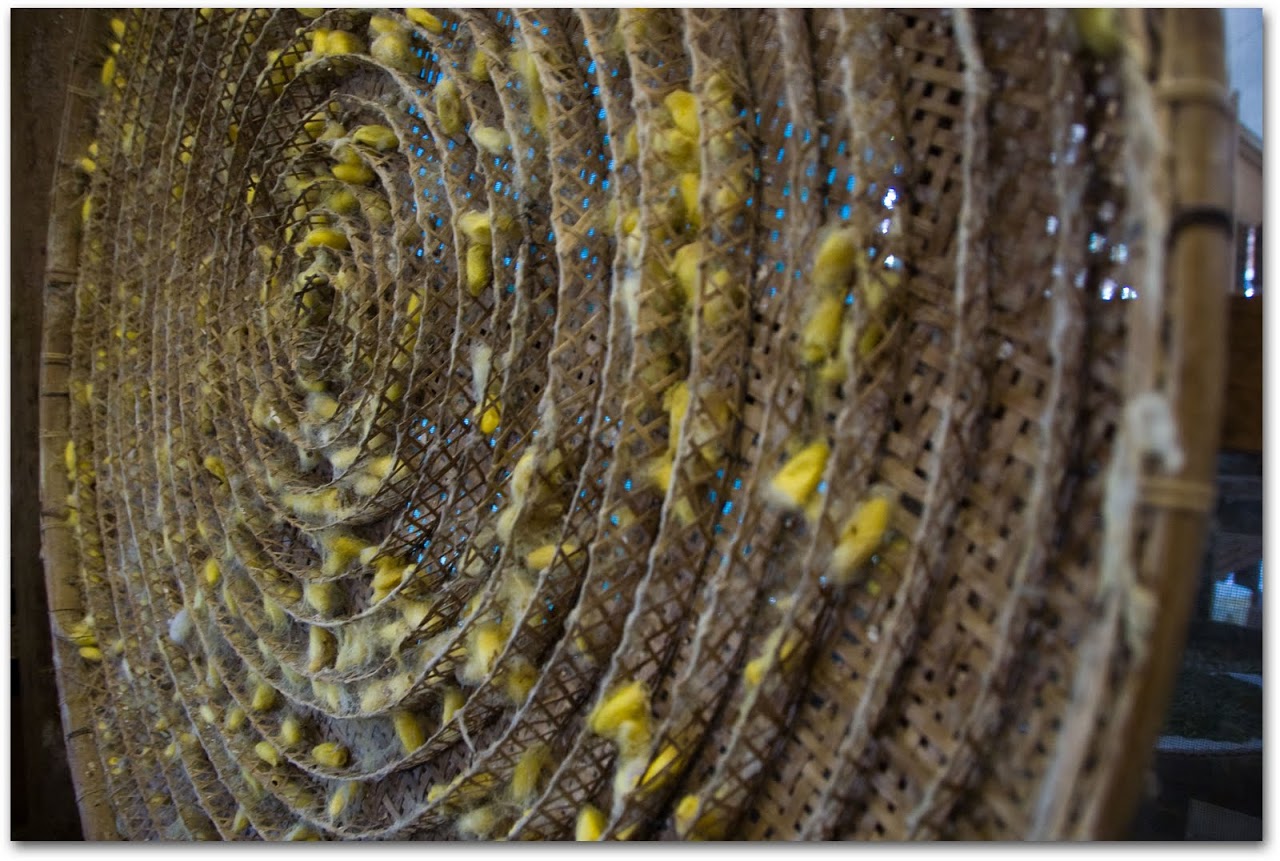

Cocoons

The silk moth lays about 500 eggs in a period of four to six days and then dies. The eggs grow into small worms which became adults in about 20 days. According to Wikipedia, in order to produce 2 pounds of silk, 3000 silkworms need to eat 230 pounds of mulberry leaves. The silk worms spin cocoons to turn into moths. About 75% of the cocoons are used in the silk weaving process and the remaining 25% hatch from the cocoons into moths to produce more eggs.

Cocoons ready to be boiled

The workers boil the cocoons with the live moths inside. Frankly, I find this disgusting. I know that they are insects, it is questionable whether they can feel pain, and most people don't care if they live or die, but it seems wrong to me to boil an insect alive in the name of fashion. But, maybe I am just being overly sensitive. (Apparently, there is a type of silk promoted by Mahatma Gandhi called Ahimsa Silk made from cocoons in which the pupae have been extracted or have naturally flown away.)

|

|

|

|

Rough silk threads extracted from boiled cocoons

A woman sits with a hand crank all day long to extract the rough silk threads from the boiled cocoons which are then dyed using natural and artificial dyes. The women spin the silk into even thinner fibers until they glisten and glimmer like webbing from a spider.

|

|

|

|

Spinning raw silk into thin fibers

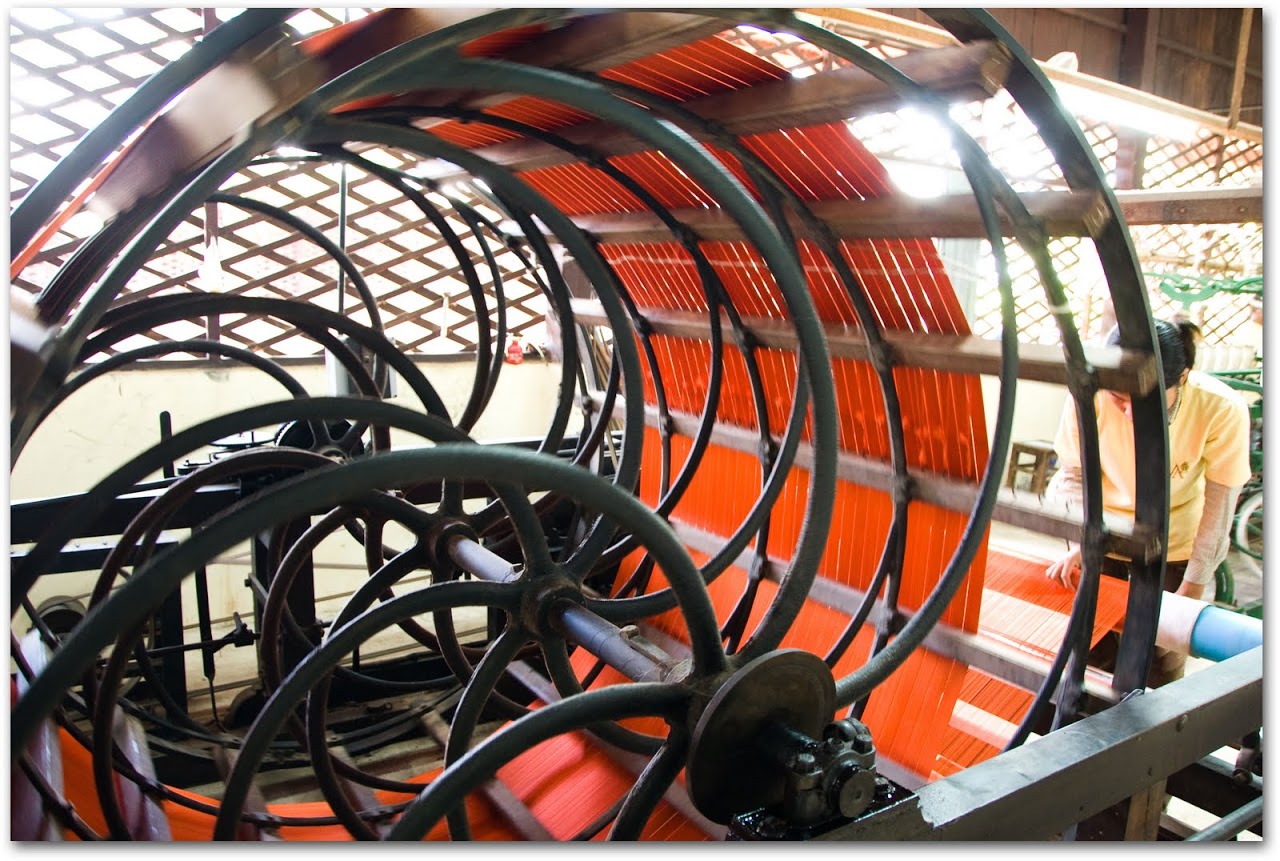

The women then convert the silk threads into amazing designs which is then woven into scarves, ties, and other fabrics with a loom. Amazingly, the women don't listen to music or watch television while performing these wholly monotonous jobs.

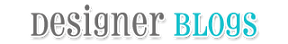

Spools of silk thread

We also saw no men working in the silk factory; perhaps silk weaving is traditionally considered "woman's work." (In the same regard, we never saw any female tuk tuk drivers.) These women work long hours and come from nearby villages to produce the beautiful products we found at the end of the tour.

Weaving silk design with a loom

Though we purchased nothing at Artisans d'Angkor, we have gained a newfound appreciation for this labor-intensive and beautiful material.

The silk tour is free and leaves every day at 9:30 and 1:30 from Artisans d'Angkor in Stung Thmey Street, Siem Reap. It is a fun break from temple visiting and a good place to buy local crafts.